Prensa punzonadora neumática de alta velocidad

15 de octubre de 2025

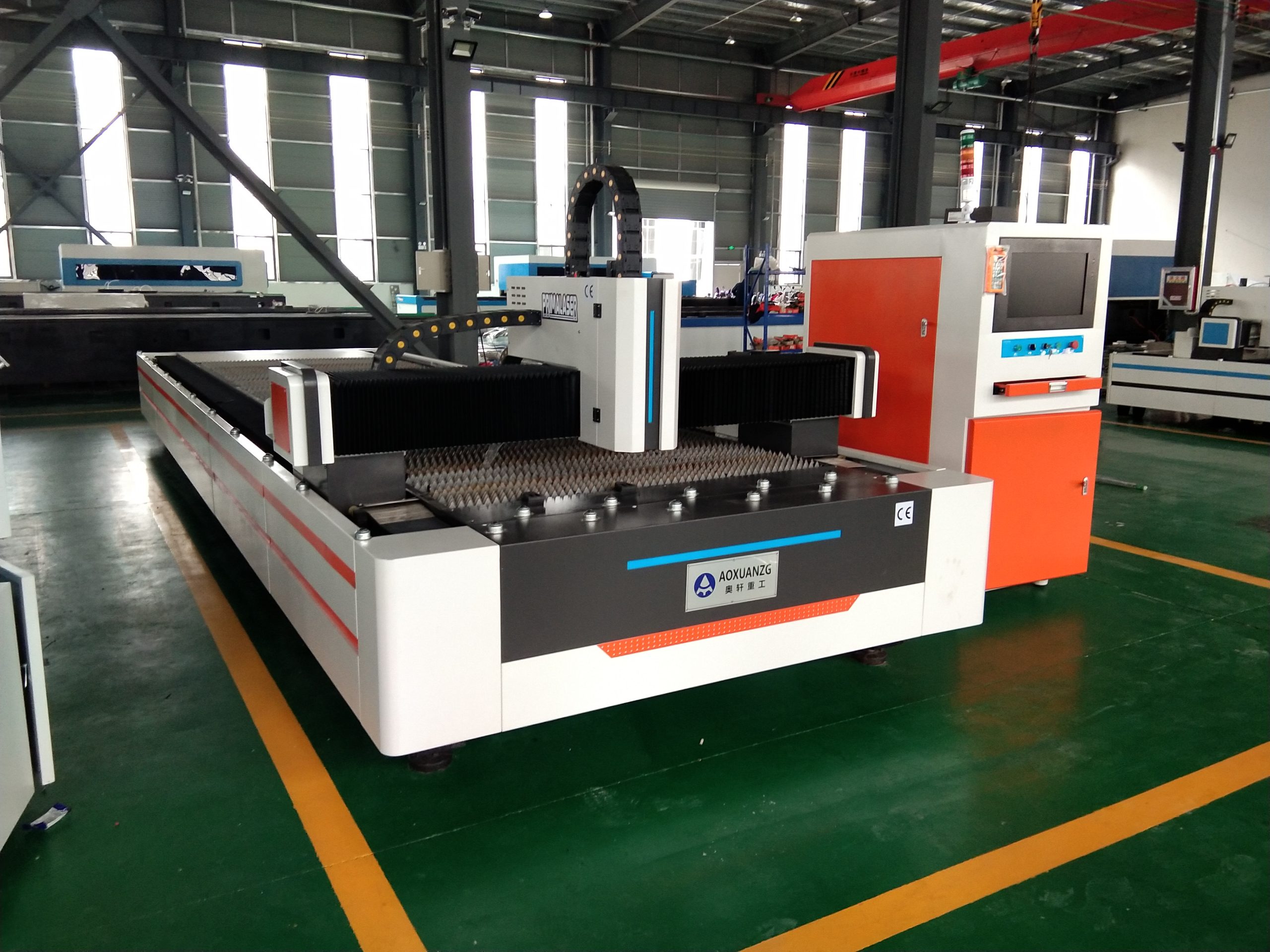

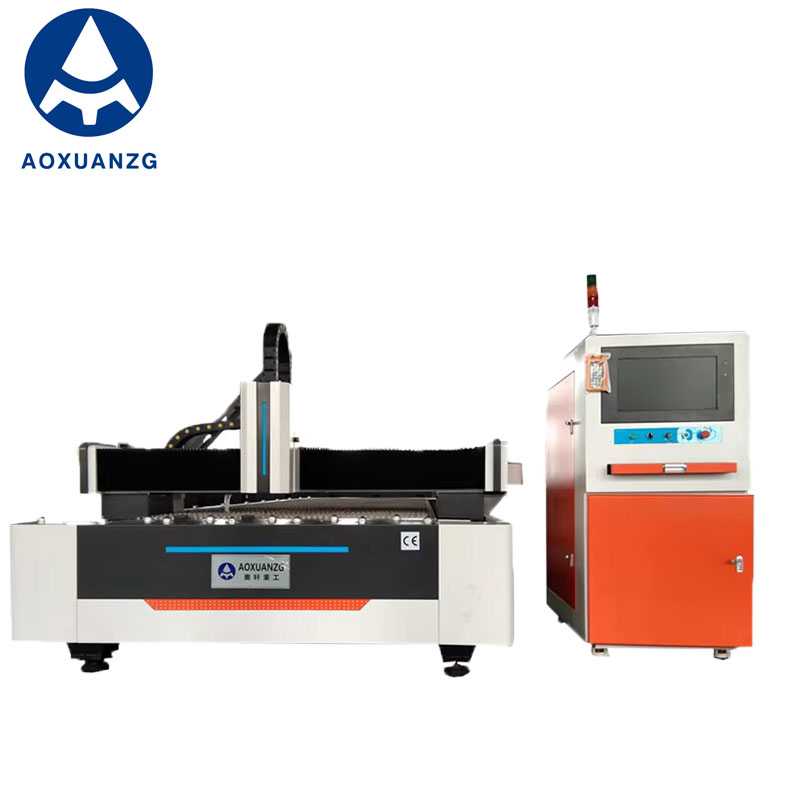

Máquina cortadora láser de fibra de alta precisión serie 3015 para el procesamiento de chapa de acero

15 de octubre de 2025Máquina de corte láser de fibra de mesa única de 1000 W y 1500 W a precio de fábrica

Las máquinas de corte láser generalmente se componen de un generador láser, un sistema de movimiento CNC, un cabezal de corte, una mesa de operaciones, una fuente de aire, una fuente de agua y un sistema de extracción de humos. Sus métodos de procesamiento se caracterizan por su alta precisión y bajos costos de procesamiento. También se caracterizan por su operación sencilla y un bajo nivel de errores.

-

dólar estadounidense ($) - Dólar estadounidense

Descripción del Producto

Descripción del Producto

Ampliamente utilizado en aviación, aeroespacial, armas, barcos, automóviles, petroquímicos, médicos, piezas mecánicas, medidores eléctricos.

piezas, hojas de sierra, virutas de resorte, hardware, volumen de cuchillas, estructuras de chapa metálica, producción de gabinetes eléctricos de alto y bajo voltaje,

Producción de carteles publicitarios, artesanías en metal, artículos de cocina, decoración y otras industrias.

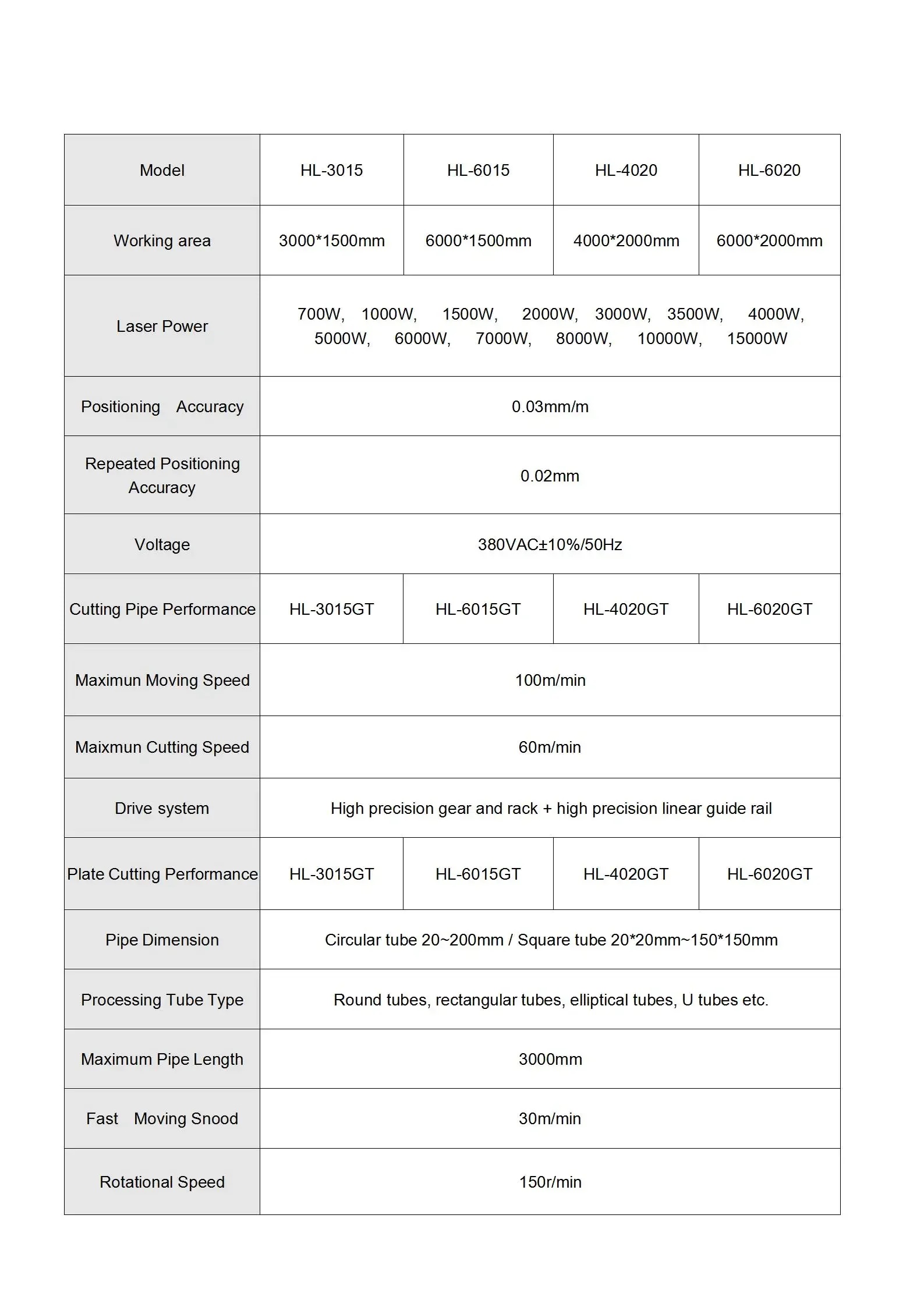

Parámetros del producto

● Excelente calidad del haz: punto de enfoque más pequeño, líneas de corte más finas, mayor eficiencia de trabajo y mejor calidad de procesamiento;

● Velocidad de corte extremadamente alta: el doble que la máquina de corte láser de CO2 con la misma potencia;

● Estabilidad extremadamente alta: Los láseres de fibra importados del mundo se utilizan para un rendimiento estable y la vida útil de los componentes clave.

Los componentes pueden alcanzar las 100.000 horas;

● Alta eficiencia de conversión electroóptica: La máquina de corte por láser de fibra tiene una eficiencia de conversión óptica 3 veces mayor.

que el corte por láser de CO2 electromecánico, que ahorra energía y protege el medio ambiente;

Certificados

Vitrina de la fábrica

Vitrina de la fábrica